Masterflex in pharmaceutical solutions

Masterflex and Ismatec brands of peristaltic pumps feature the contamination-free pumping technology favored by regulated industries.

Our Single-use Solutions and Custom Cut Tubing services are ready to provide you with custom gamma-irradiated single-use tubing assemblies and tubing cut to the lengths and quantities you need. In addition to the products we offer, our representatives are familiar with the challenges you face and the services you require.

Masterflex peristaltic pumps are perfect for

- Tangential flow filtration

- Harvesting cell media

- Bioprocess workflows

- Purification

- Manufacturing IV bag dispensing

- Spiral ultrafiltration

- Fermentation control

- Dissolution testers

- Cosmetic dispensing

What makes Masterflex a top choice for pharmaceutical applications

- Wide range of tubing materials - Compatible with many laboratory chemicals.

- Noncontaminating - Fluid media only contacts inside of tubing.

- Easy cleanup - Just change the tubing to clean the pump.

- Multichannel capability - Use up to 32 channels simultaneously on one drive.

- Sanitary connections on tubing - Quick tubing connections within sanitary systems.

- Handles viscous materials - Dispense agars and suspensions.

- Runs dry - Use as a low-flow aspirator or air/vacuum pump.

- Modular design - Mix and match pump heads, tubing, and drives.

- Custom Engineered Service - Design into your lab dispensers or analytical equipment.

Masterflex in buffer media preparation

Pumps, fluid path components, mixing equipment, filtration and process monitoring are all important pieces of a complete buffer preparation system.

Buffer solutions are essential to effective harvesting and purification. Maintaining buffer purity while providing accurate volumes is critical for effective production.

Media prep workflow

Masterflex in cell culture transfer applications

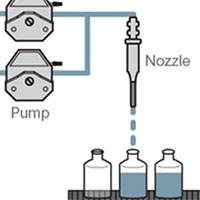

Peristaltic pumps, with sterilized tubing and connectors, are ideal methods to protect the purity of your culture when transferring between production vessels.

The cell culture is the primary production environment for biopharmaceutical products. During pilot and scale-up operations, maintaining optimal conditions for cell growth through gentle treatment of the culture medium is important to ensure maximum yield of final product.

Media Feed Pump

Efficient, programmable feed and filling of media; flows to 19 LPM

Dispensing Pump

Versatile multichannel pumps for accurate low-flow fluid delivery – with an intuitive touch-screen interface

Acid/Base Feed Pump

Programmable dosing of pH adjusters and other adjuncts; flows to 3400 mL/min

Peristaltic Pump Tubing

Masterflex and Ismatec precision extruded and pump tested formulations engineered for the highest reliability, compliance, and traceability

Sanitary Fittings and Clamps

Ensure secure, sanitary connections in critical process applications. Fittings and clamps in sizes needed from pilot to production

Masterflex in tangential flow filtration (TFF)

Masterflex offers pumps, fluid path tubing and connectors, filtration, pressure monitors and other products to ensure success while protecting the purity of your end products.

Used to separate and/or purify biomolecules and harvest cells, TFF’s working pressures and flow rates require the appropriate equipment.

Revolutionary diagnostic therapeutics call for custom pumps

In the healthcare industry, both safety and time are priorities. Product developers from Cytonics turned to Masterflex’s Custom Engineering Services Group to create a custom pump solution for their APIC system.

Learn more